Avoid expensive recalls and protect your brand’s reputation

Why use Detectable Materials?

Detectamet are the leading Metal and X-Ray Detectable Food Safety Product Supplier. As part of good food processing practice, we recommend detectable materials are used throughout your production line & detection systems are calibrated regularly. Physical contaminants within the food production process can damage equipment and cause injury. If these contaminants aren't detected and they reach the consumer, your company will be faced with an expensive recall, which could seriously harm your brand's reputation.

The safest way to eliminate and protect against this risk is to use our metal detectable and X-ray visible products in all areas of your processing facility.

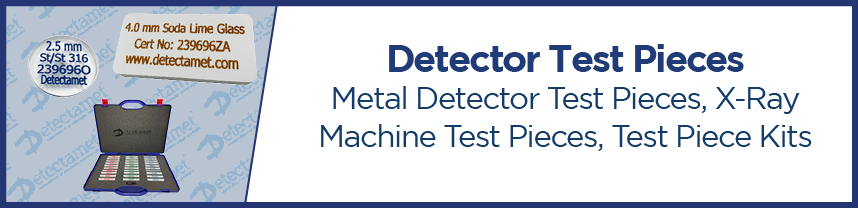

Our Detectable Products

Made from a unique, patented EU & FDA food contact approved polymer that contains the highest level of detectable additive, our product range offers you the best in detectability without compromising on durability.

To request a Free Sample of a product listed on our website, and/or a Detectamet Catalogue, contact your local Detectamet branch or follow the below link.

Detectamet USA (English - $ USD ) Click here to change your currency, region and language.

Detectamet USA (English - $ USD ) Click here to change your currency, region and language.